When people think about Venetian Plaster it is typically associated with the classic smooth and super high gloss finish plaster. Some maybe even think it’s a product that is sold in a gallon paint can at your local hardware or home improvement store. Then, you have those that have not even heard of it. Although Venetian Plaster has been around since ancient times, it is true that not everyone knows it exists. So how do you sell something not everyone knows or understands? Hello. My name is Ashley. I have spent half my life surrounded by this trade. I worked for one of the first importers in the United States of these types of products for nearly 14 years and over that time I heard numerous consumers’ questions regarding Venetian Plaster. One of my favorite topics was the actual process of making Authentic Venetian Plaster.

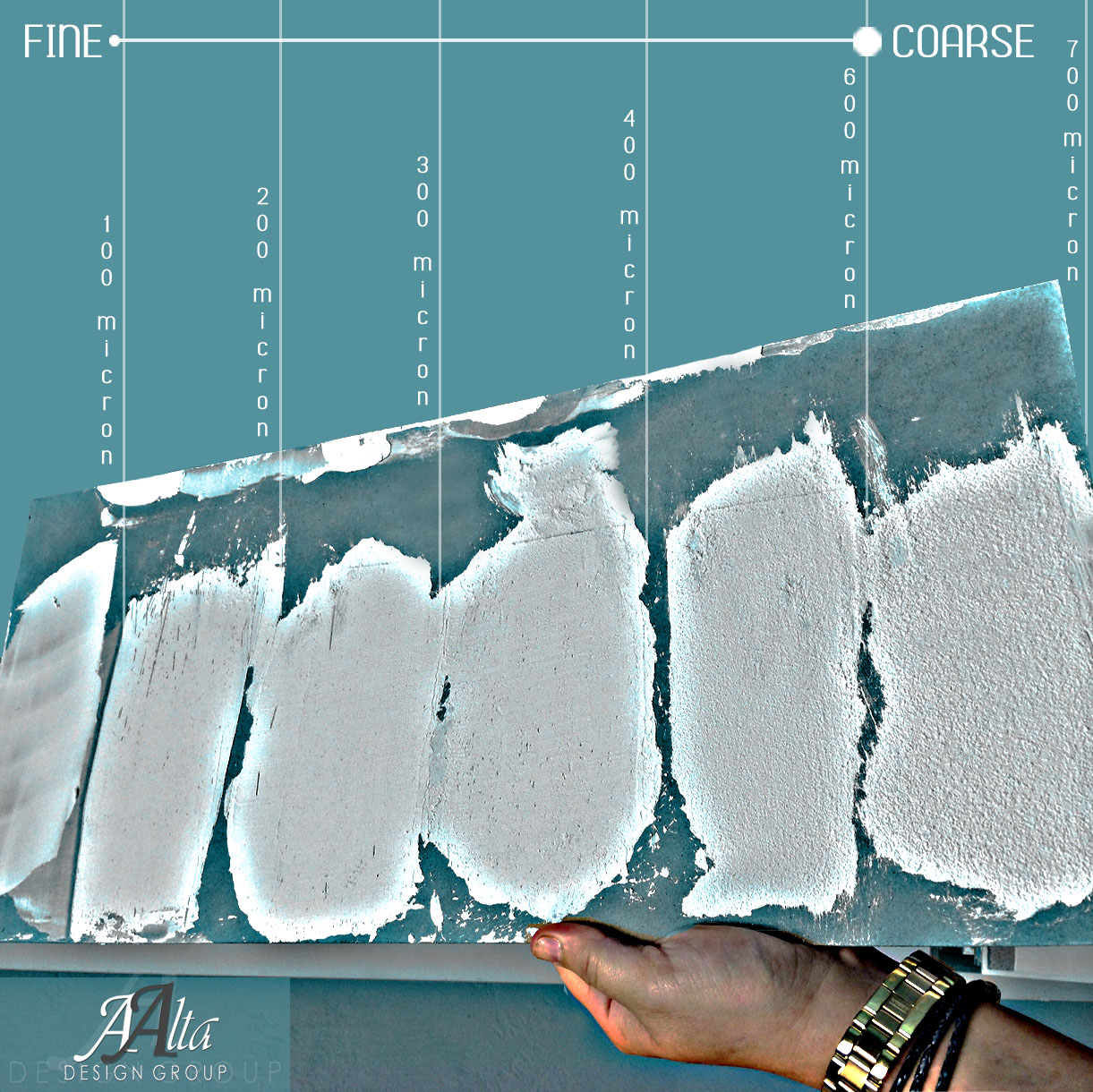

The process begins with taking a big piece of lime. You have two options now. The first is to take this big slab of lime and bake it in an oven with high temperatures. Once the baking process is complete the manufacturer will take it and pour water on it causing the slab of lime to melt down becoming slaked lime. They put the slaked lime in a vat. The second option they can go when the manufacturer gets the slab of lime is to crush it into pieces, tiny, tiny, pieces. They take the pieces and sift them through a machine that contains metal nets. These metal nets have different size holes measured in microns. A micron is a unit of length equal to one millionth of a meter, used in many technological and scientific fields. The smallest holes in the nets that they use are equal to 100 micron. They change by hundreds, upwards to 800 microns. The smaller the micron, the smaller the crushed lime aggregate that can fit through the net.

Picture this….if you have ever baked something that requires you to sift flour, it’s the same concept. So when they pour the crushed lime down the machine the smallest aggregates fall through all the nets and gets captured into a big barrel below which is put off to the side to be used later, labeled 100 microns. Next, they use the 200 micron net to sift anything that will fit through from the remaining crushed aggregate. This is captured in a 200 micron barrel at the bottom and set aside for later use. They keep doing this process until all the different size microns of the lime have been gathered separately and put aside for future use. So now you have the melted down slaked lime and you have different lime aggregates measuring in different size microns. Now the scientists make concoctions.

It makes sense if you want a final product to be smooth like the classic high gloss, it will contain the smallest aggregate which would be 100 microns. Let’s say you want a rustic plaster you can do a skip trowel affect with, you would probably want to use the 600 or 700 micron aggregate plaster or maybe even both 600 and 700 microns to have a less consistent look. One of the most popular matte plasters that I have sold was a smooth consistent looking matte plaster containing 400 microns. There is really no limit on concoctions the scientist can make using the slaked lime and mixing it with different microns of lime based aggregates. Before giving the final product to the client the slaked lime must sit and mature for a period of around six months. This makes for a more premium final product.

So now that you know how Venetian Plaster is made in Europe, you can have a better understanding why this is a more premium product than what is sold at your local hardware or home improvement store. In fact, that’s a whole different topic we will cover another time. Instead, let’s go back to the question we asked “So how do you sell something not everyone knows or understands?” The answer is…the best way to sell anything is to know what you’re selling. Product knowledge is the key. The more confident and knowledgeable you are about your field, the easier it will be for you to enlighten your clients and close deals on projects.

Thank you for reading our blog piece and we invite all alike to keep coming back for more educational pieces. We love what we do. We’re good at what we do. We don’t mind helping out others at the same time too. Thanks again and see you next time.

For more information or if you need any collaboration on any projects call us at 786-442-4000.